Cement lining

TRENCHLESS WATER PIPE RESTORATION USING THE CEMENT LINING METHOD

Cement lining is the most common method of providing additional protection to the internal surface of water pipes. This traditional trenchless method is most commonly used for drinking and utility water pipes as well as for sewers.

PIPE TYPES SUITABLE FOR THIS METHOD

Cement lining is suitable for the trenchless restoration of pipes with DN 200–1,200 mm. The pipe material can be steel, cast iron, or asbestos cement.

HOW IT WORKS

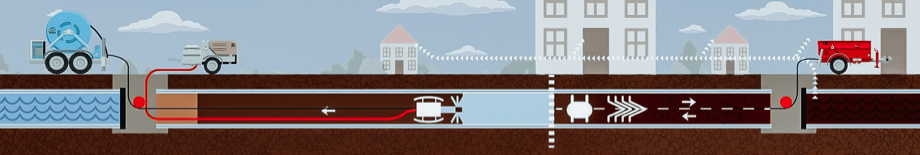

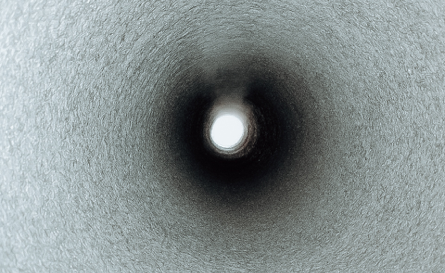

The cement mixture is applied to the cleaned interior surface of the pipe using a rotating head machine winched through the pipe, which can accommodate pipes of DN 200–1,200 mm. The standard range of the cement lining thickness is 3–12 mm; however, we can modify the thickness at the client’s request. Trenchless pipe refurbishment using cement lining is quick and environmentally friendly.

CEMENTING PROCESS

- Opening access to the pipe from both sides

- Mechanical cleaning of the pipe surface

- Cement mortar application using a winched application machine

- Video inspection

- Re-connecting the restored pipe to the water system

- Commissioning

BENEFITS OF TRENCHLESS RESTORATION USING CEMENT LINING

- Cement lining guarantees that the drinking water in the pipeline remains completely safe.

- The quality of the water supplied remains constant. The cement liner prevents iron oxide leaching from original iron piping walls.

- The cement liner also protects the pipe interior from corrosion.

- There is no scaling on the interior pipe surface.

- Cement lining re-improves the hydraulic properties of the pipeline surface.

MORE DETAILS ABOUT THE TECHNOLOGY

- We use specialised pre-mixed cement mortar for pipe rehabilitation.

- Our mortar mixtures are certified and contain pure silica sand with grains 2 mm maximum in size, cement, and drinking water.

- We clean the pipes mechanically using a Bagela winch and special scrapers, plungers, and brushes.