Cleaning, monitoring, and repairing pipes using robots

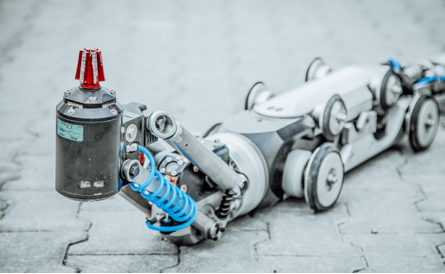

We can clean a pipe quickly and efficiently, and then scan it to determine its condition. We use cutting-edge crawler robots for work in piping systems of various dimensions. Each crawler is adapted and equipped to the activity for which it is used. We have a crawler robot for pre-rehab preparatory work that removes any obstacles, another robot that can re-open service pipes covered during the lining process, and yet another robot that ensures watertight connection of service pipes to the main sewer pipe using hat liners. Experienced operators control the crawlers from a special vehicle cabin. We possess monitoring crawlers fitted with various types of cameras. Having completed the inspection and diagnosis, we propose a solution tailored to the issues detected in the pipe.

ISSUES THAT CUTTING ROBOTS CAN TACKLE

- Offset connections – different height or direction

- Disruptive roots

- Incrustations, concrete, missing shards

- Foreign objects – steel, cast iron, wood, plastic

- Re-opening service pipes after the lining

PIPELINES SUITABLE FOR THE USE OF CRAWLER ROBOTS

Crawlers can navigate pipe profiles of DN 150–600 mm. For oval pipe profiles, we use specially adapted carriages for DN 300/450–500/750 mm pipes.

HOW IT WORKS

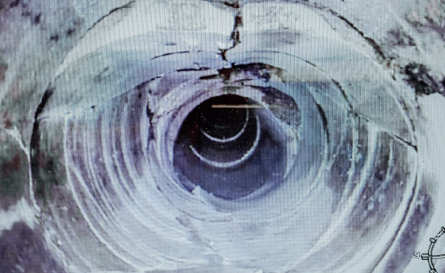

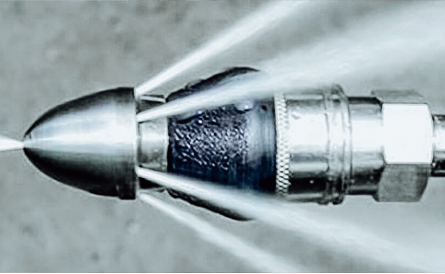

We initially clean the pipe and remove any scaling. The moving camera inspects the pipe and takes detailed pictures of any defects detected. Following the initial diagnosis and video evaluation, we prepare a list of defects and attach a bid for their repair using trenchless technologies. Only in exceptional cases do we recommend different rehabilitation methods. We then undertake the job using sewer crawlers which remove any obstacles that could impede trenchless repairs. The operator watches the robot working on a monitor and controls it using joysticks and other controls.

COURSE OF THE WORK

- Cleaning the pipe of sediments and scaling

- Video inspection of the pipe

- Evaluation of inspection results and diagnosing

- Cataloguing the data in a pipe ‘passport’ (CD, DVD)

- Proposing a solution to the pipe issues

- Rectifying local defects or overall rehabilitation

TECHNICAL DETAILS OF THE WORK PERFORMED BY MONITORING ROBOTS

- Cameras are used to survey and document the structural and technical condition of the pipe, as well as to control the quality of the rehabilitation work.

- The colour code used in the pipe inspection record conforms to ČSN EN 135008-2 standard.

- Our crawlers are fitted with IBOS – CamBoss, IBAK (Orion, Rigid) and Itv cameras.

- The CamBoss, IBAK, and Itv cameras have a rotating head and are used for pipe profiles of DN 100–1600 mm.

- The IBAK Orion push-in camera with a rotating head is used primarily for monitoring home service pipes of DN 80–200 mm. Using the push rod, it moves at distances of up to 50 metres, managing bends and angles (depending on the pipe profile and bend radius).

- The Rigid inspection microsystem is used to monitor smaller profile pipes from DN 30 mm to a maximum length of 5 metres. This inspection cannot be recorded.

OUR CERTIFICATION

Certificate of camera system operator course according to EN ISO 9001 and ISYNBAU standards