INSAK – new hardened plastic pipes within legacy sewers

The INSAK technology is a trenchless inverse sleeve method and is suitable for refurbishing different sewer pipes, regardless of their material or shape.

PIPE TYPES SUITABLE FOR THIS METHOD

The INSAK method can be used for refurbishing various sewer pipe types, regardless of their material or shape. The sleeve we manufacture is of a precisely calculated thickness and conforms to the dimensions (circumference, DN, length) of a specific pipe.

PROPERTIES OF THE INSAK SLEEVES

The outer layer of the sleeve is an impermeable PVC foil that forms a smooth internal surface in the pipe being refurbished. This improves the flow rate and sealing of the restored pipe. In addition, the refurbished sewers become more flexible, so the pipes do not rupture in unstable soil.

HOW IT WORKS

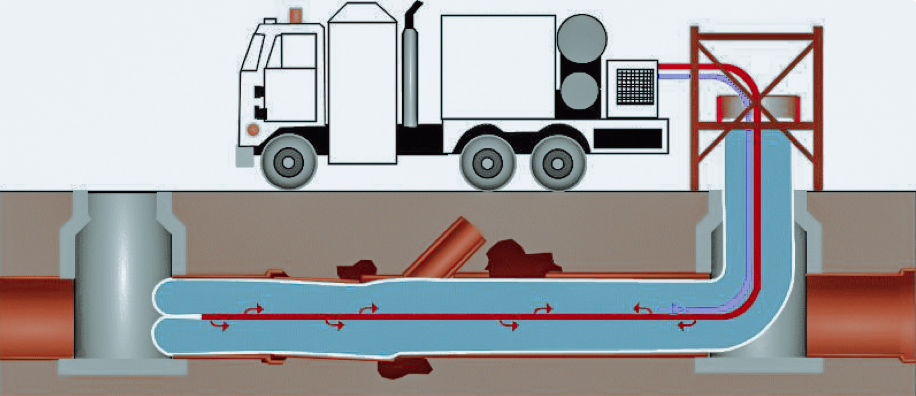

A flexible sleeve formed from one or multiple layers of unwoven fabric utilising man-made fibre is introduced into a cleaned sewer pipe using hydrostatic or air pressure. The sleeve is infused with a suitably formulated resin. The fabric sleeve cures by polymerisation, effectively creating an entirely new, hardened plastic pipe inside a damaged sewer. The process of installing the sleeve is quick and environmentally friendly.

INSTALLATION PROCESS

- Opening access to the pipe from both sides

- Cleaning the sewer pipe to be refurbished

- Cutting away all obstacles using a robotic device

- Locating sewer pipes and inspecting the pipe using CCTV

- Installing an inverse sleeve and curing it by polymerisation

- Cleaning the joint between the shaft wall and the liner

- Re-opening covered branch pipes using a robotic cutter

- CCTV inspection recorded on CD/DVD/SD

- Commissioning

BENEFITS OF TRENCHLESS REFURBISHMENT USING THE INSAK METHOD

- The outer layer of the sleeve is covered with an impermeable PVC foil, ensuring that it remains airtight and protected during saturation, transport, and installation. Once cured in the pipe, the foil forms a smooth internal surface.

- The liner adheres strongly to the pipe, copying its irregularities and resisting abrasion and chemicals.

- The method addresses structural integrity issues associated with the piping and improves its hydraulic parameters. At the same time, it improves its flow rate and seals it completely.

- The refurbished pipe exhibits increased flexibility and will not rupture, even in unstable soil.

- The process of refurbishment is rapid – as much as 200 metres in 2 days.

- The method is especially environmentally friendly.

MORE DETAILS ABOUT THE TECHNOLOGY

- We always manufacture the sleeve to a precisely calculated thickness which conforms to the dimensions of a specific pipe (circumference, DN, length).

- We are the only business in the Czech Republic providing trenchless refurbishment using proprietary equipment for sleeve manufacturing (a sewing line, a welding bench) and tensile testing (tensile tester).

- We determine the thickness of the sleeve wall on the basis of a structural calculation that takes into consideration the pipe’s profile, degree of damage, and installation depth, as well as groundwater level.

- We install the liner in the piping using the inverted method in accordance with ČSN EN ISO 11296-4 and ATV-M-127-2:2000 standards.

- During the pressurising and curing process, we monitor and record essential parameters.

- Once the process is finished, the robotic cutting device re-opens the covered branch pipes. If requested, we can fit the connection of the branch pipe to the sewer with a hat. Branch pipes can be reopened manually in man-sized pipes, including bricklayer work.

- Once the work inside the pipe is completed, we inspect the pipe using CCTV and record the inspection.

OUR CERTIFICATION

We hold EN ISO 9001:2008 and EN ISO 14001:2004 quality certification. Certificate No. 204/C5a/2019/090-044824 for the product Refurbishment Liner for Sewer Pipe Systems and Industrial and Raw Water Supply Pipes – INSAK® System, dated 29 May 2019 (Technical and Test Institute for Construction Prague).