Primus Line

FLEXIBLE TECHNOLOGY FOR TRENCHLESS RENOVATION OF PRESSURISED PIPES

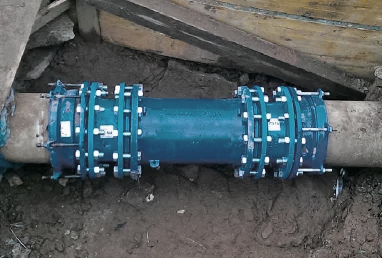

Primus Line® is an innovative technology for the trenchless rehabilitation of pressurised pipes used for various media such as water, gas, and crude oil. The process is based on a flexible, seamless high-pressure liner and special connectors developed exclusively for this system. Primus Line® is suitable for the transport of various liquids in the water industry and is certified for drinking water in multiple countries. Ideal hydraulic properties resulting from an extremely smooth interior lining and a comprehensive system for a wide range of operating pressures (including high pressure) make Primus Line® a cost-effective solution for rehabilitating ageing pipes. Water management companies and utility operators can therefore benefit from reliable operation and sustainable investments in their fixed assets.

Primus Line® is ideal for rapid and reliable rehabilitation of damaged pressurised piping with profiles ranging from DN 150 to DN 500. It can tackle multiple bends whilst achieving an installation length of up to 2,500 metres.

- Drinking water

- Fire-fighting water

- Industrial water

- Seawater

- Wastewater

SAVES TIME AND MONEY

- Installation rate up to 10 metres per minute

- Up to 2,500 metres in one go

- Rapid re-commissioning minimising outages

SIMPLIFIES YOUR ENGINEERING PROCESS

- Installation through multiple bends of up to 45° or more (subject to a case-by-case assessment)

- Withstands thermal expansion of the existing pipes and deformations due to depression and seismic influences

- Fully flexible seamless Kevlar fabric

PROTECTS THE ENVIRONMENT

- Minimal impact of the installation

- Small installation pits; reduced roadwork

- Minimal use of machinery

- Reduced adverse effects on traffic

- Minimal disruption of everyday life in the vicinity

ALLOWS INCREASED OPERATING PRESSURE

- Operating pressure of up to 82 bar

- Independent of the existing pipe

- Burst pressure of up to 206 bar

EXTENDS SERVICE LIFE

- 100% quality control during manufacturing and prior to shipment

- No curing, steaming, or gluing

- Installation process independent of weather

- Service life of 50 years or longer