Trenchless water pipe restoration using SAERTEX-LINER H₂O liners

The unique SAERTEX-LINER H₂O technology is one of the trenchless sleeve methods. It is a quick, clean, and highly precise refurbishment method. We are the only organisation in the Czech Republic to use this method.

PIPE TYPES SUITABLE FOR THIS METHOD

SAERTEX-LINER H₂O liners are suitable for the trenchless restoration of pressurised pipes with dimensions of DN 200–1,500 mm. The maximum possible sleeve length is 320 metres.

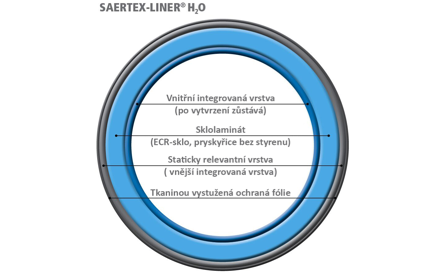

PROPERTIES OF THE SAERTEX-LINER H₂O LINER

The excellent mechanical properties of the sleeve allow for use under high pressure whilst reducing the thickness of the sleeve wall. The sleeve’s smooth surface and thin wall considerably improve the pipe’s hydraulic properties. The sleeve can bear extreme external and internal loading, including both overpressure and vacuum.

Internal integrated layer (remains after curing)

Fibreglass (ECR-glass, styrene-free resin)

Structurally relevant layer (external integrated layer)

Fabric-reinforced protective foil

HOW IT WORKS

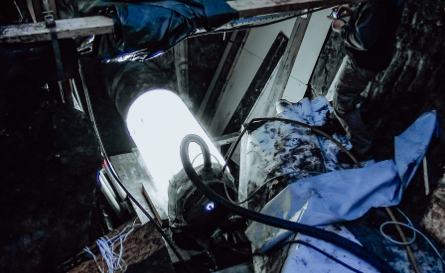

The SAERTEX-LINER H₂O seamless glass fibre sleeves with a grid structure are impregnated with a vinyl ester resin without styrene during production. A sleeve is drawn into a cleaned pipe and the resin is cured using UV lamps. As a result, an entirely new, self-supporting pipe is created. The process of installing the sleeve is quick and environmentally friendly.

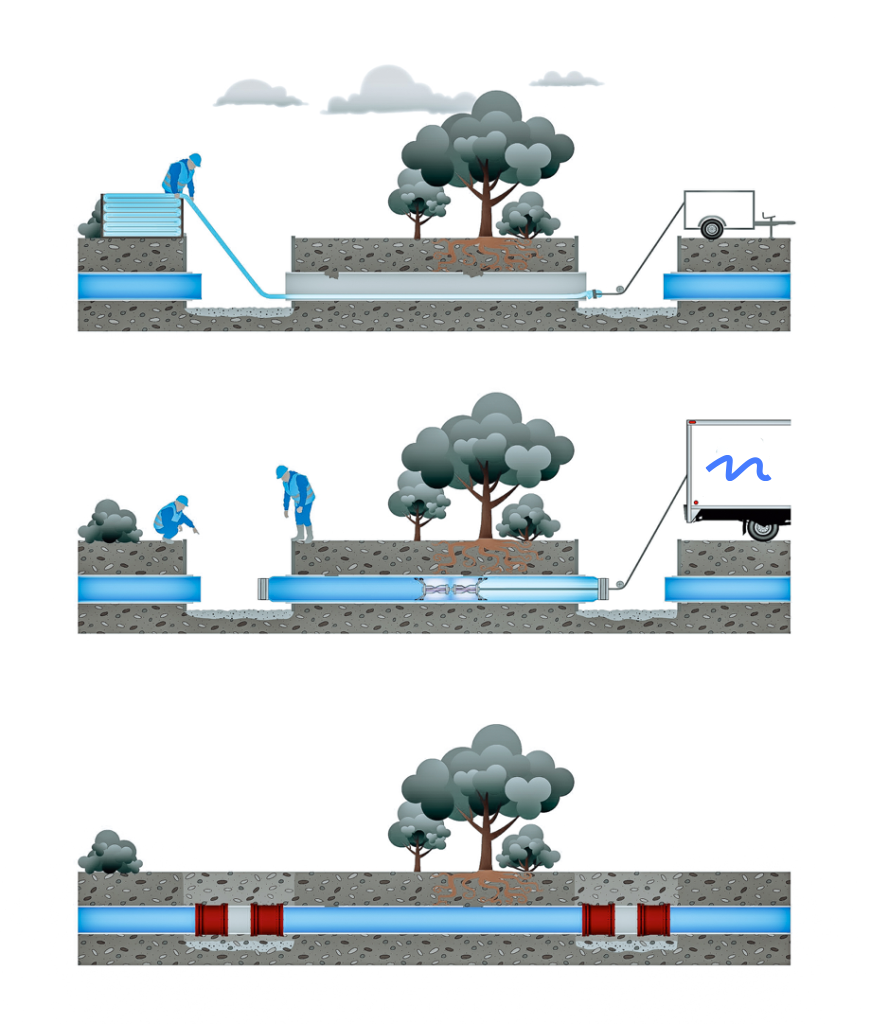

INSTALLATION PROCESS

- Opening access to the pipe from both sides

- Induction of a SAERTEX-LINER H₂O sleeve

- Inflating and curing the sleeve using UV rays

- Video inspection

- Re-connecting the restored pipe to the water system

- Commissioning

BENEFITS OF THE TRENCHLESS INSTALLATION OF SAERTEX-LINER H₂O SLEEVES

- During the installation, the inner layer of the sleeve is situated inside and protected, preventing the contamination of drinking water.

- The sleeve is not ‘glued’ to the old pipe. Therefore, cleaning the pipe down to bare metal is not required.

- The patented inner surface of the sleeve with an integrated barrier guarantees efficient application of the UV curing method.

- Sleeves can be stored for long periods (up to six months), allowing for a high degree of flexibility in planning refurbishment work.

- Unlike standard cementing processes, pipes restored using sleeves have a much longer service life – up to 80 to120 years.

FURTHER DETAILS ABOUT THE TECHNOLOGY

- We always manufacture the sleeve to a precisely calculated thickness which conforms to the dimensions of a specific pipe. Sleeves are manufactured in an ISO 9001-certified plant.

- We guarantee optimal production conditions and cleanliness in order to meet the high sanitary standards for drinking water.

- Our lab personnel carefully inspect and document the quality of all materials, particularly the resin mixture.

- We monitor and record essential parameters during the actual installation, pressurisation, and UV curing of the sleeve.

STRUCTURAL CLASSIFICATION OF LINERS ACCORDING TO DIN EN ISO 11295/AWWA M28

- Class A/Class IV: tightly attached – independent, fully statically loadable liner

- Class B/Class III: inherent ring stiffness – interactive, semi-structural liner

OUR CERTIFICATION

Czech Republic: SZÚ – EX 170029, No. 66/2017

Slovakia: RÚVZ – No. 33/2017

Germany: DVGW W 270 and KTW-Guideline

Poland: NIPH – NIH Hygienic Certificate

USA: NSF/ANSI Standard 61